Commercial businesses depend on reliable and safe cleaning methods to ensure their facilities meet strict regulations and to protect both their employees and customers. But choosing the right industrial cleaning method isn't always the easiest of tasks. With so many cleaning solutions available, it's often a good idea to comparison shop before making your decision. In today's post, we'll discuss the main features of some of the most popular industrial cleaning techniques and explain why one stands out above the rest.

Using water to clean is nothing revolutionary, but high-powered H2O can be a viable option for many businesses. While its performance is satisfactory, it's not the best example of environmentally sustainable cleaning. After all, you'll be using a significant amount of water to do this job. In addition, that water must completely dry before operations can resume, which can put a damper on your productivity levels and overall output. It's also important to note that if your aim is to remove contaminants like mold and mildew, water may not be the best option available; recontamination has been known to happen, especially due to the excessive drying time required. In some cases, water blasting can also be abrasive and may not be a good option for sensitive equipment that could become damaged as a result.

Sandblasting used to be the main cleaning option for many businesses, but that's changed in recent years. That's because sandblasting is quite abrasive. That can be effective for the removal of tough grime, but it can also cause damage to certain materials. And while sandblasting does allow you to achieve a smooth finish in harder-to-reach spots, it's still not as quick and effective as the last option on our list. Sand also requires some kind of cleanup because it leaves cleaning product behind, which may be a drawback for many organizations.

Soda blasting is the use of sodium bicarbonate (also known as baking soda) for cleaning. It's a relatively new kind of technology, but it uses the same principles as other types of abrasive blasting: namely, the product is applied at a high pressure to remove contaminants. Many industry professionals feel soda blasting is a gentler alternative to others on this list. However, it can't be used on all materials and produces quite a bit of secondary waste. It may be considered somewhat environmentally friendly -- but it can't hold a candle to CO2 blasting.

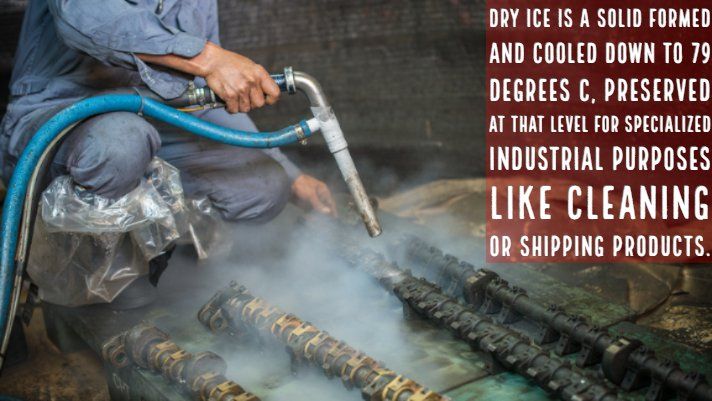

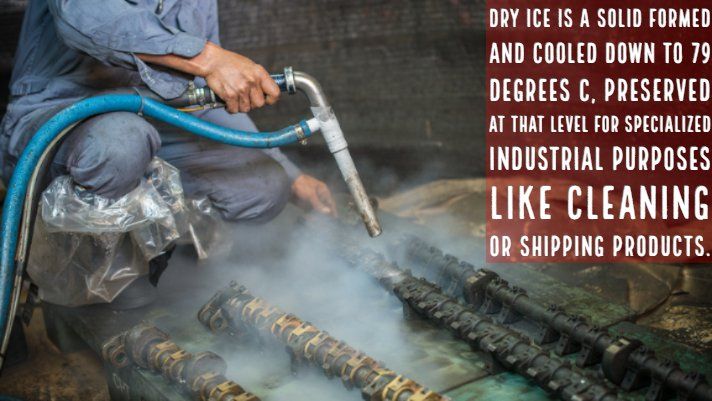

Although it was patented in 1955, dry ice blasting is a cleaning and polishing method still used by countless businesses today. Dry ice cleaning services will use pellets, which immediately transform into gas, to clean just about anything with no waste product to worry about afterward. It's also non-abrasive, environmentally sustainable, and completely safe. That's why so many organizations seek out dry ice cleaning services to help them with these needs; other options simply can't compare.

Now that you know more about the competition, it's clear why a dry ice cleaning service is the way to go. To learn more about how our services can restore health and cleanliness to your facility, please contact us today.

Contact Us

For more information on mobilization and/or scheduling:

Call or text: 469-406-1542

info@InterstateCarbonic.com

All Rights Reserved | Interstate Carbonic Enterprises | Website by Olive Street Design